XRAY Thickness Gauges

Replacement & Automation of XRAY Gauges:

Description:

Project Manager on the removal and installation of XRAY thickness gauges, including all electrical, mechanical, and fluid systems.

Automation Engineer on the integration of Thickness Gauges and Main Line PLC

Steps of Project:

1. Demo electrical and piping of old gauges

2. Remove all XRAYs and send to manufacturer for disposal, send serial #s to the state

3. Remove old XRAY gauges

4. Modify Platforms

5. Install new XRAY gauges

6. Electrical install to gauges

7. Commission new gauges

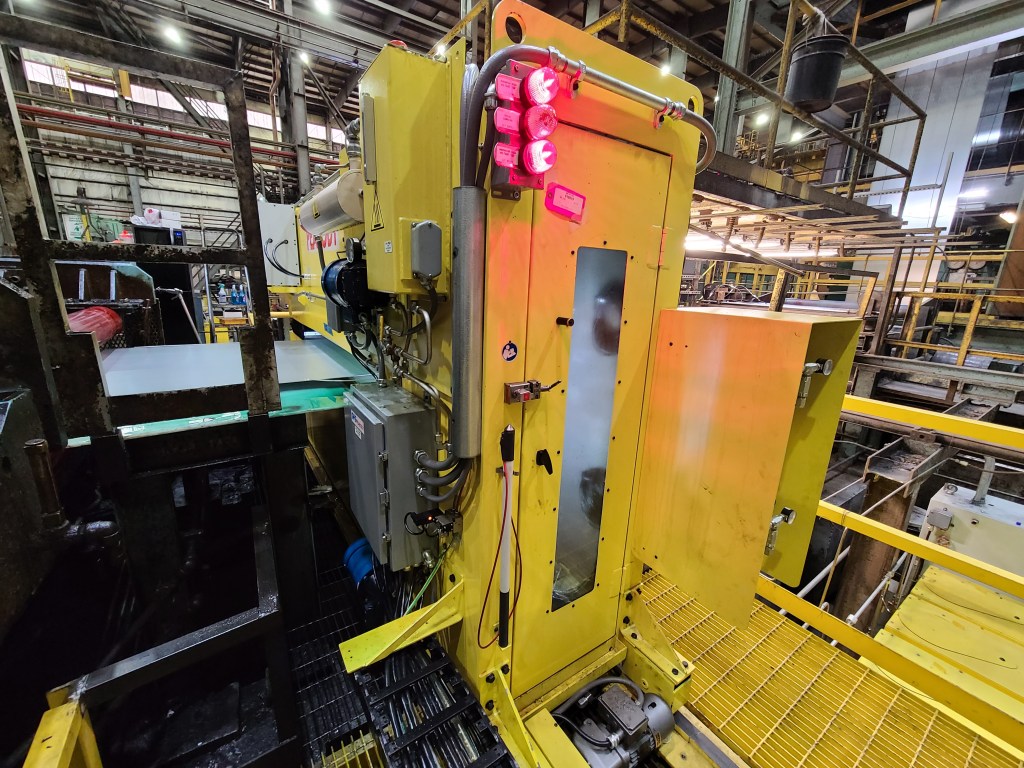

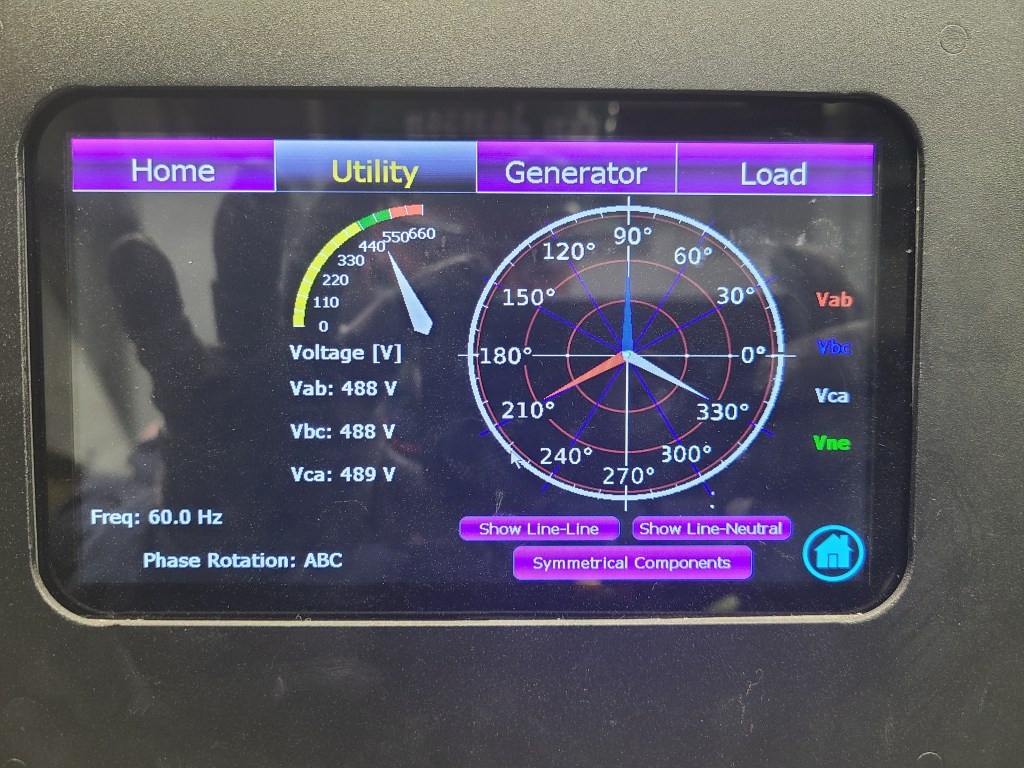

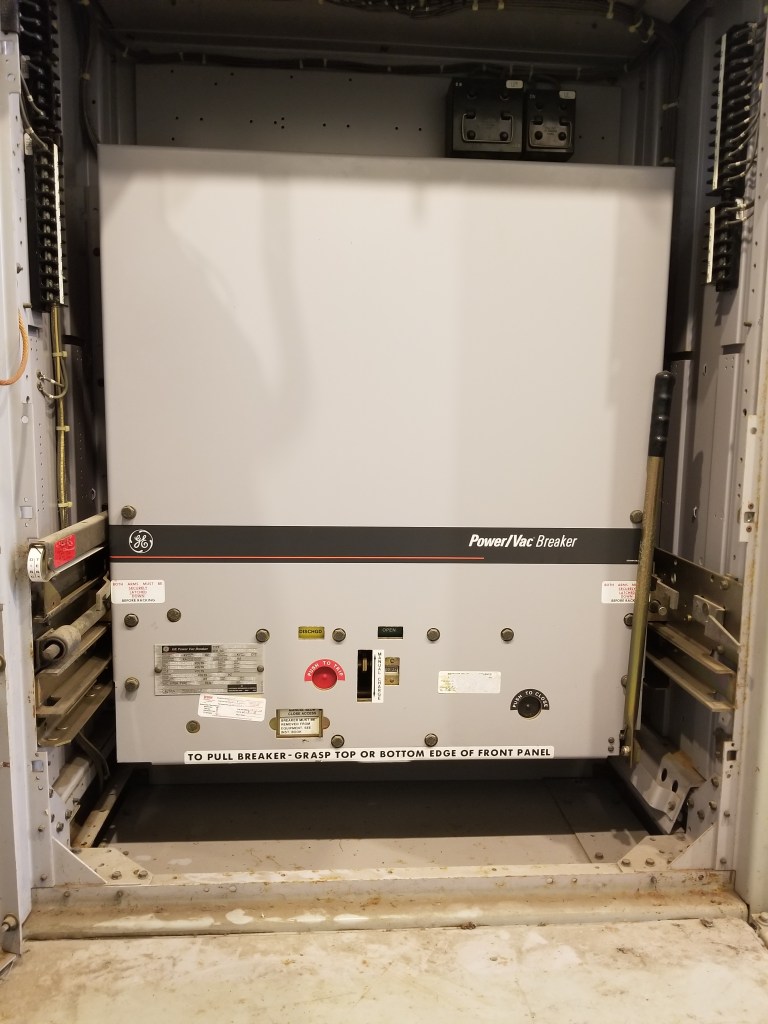

Twin Paralleling Emergency Generators

Description:

Engineered Size of Generators, length and size of cables, transformers, load banks, motor control center.

Coordinated settings for breakers and mains throughout system.

Lead Project Engineer over entire install and testing.

Also lead R&D over creative use of system.

Steps of Project:

• Two 500KW Paralleling Generators in outdoor enclosures

• Two 1000 gal Diesel tanks attached to enclosures

• 7 section MCC

• 500KW Resistor Load Bank

• New 380KVA Transformer

• Multiple cable runs, all of which I engineered for <3% voltage drop at full load

• 3 disconnects

• And power supply internal upgrades

• Redundant PLC panel for full automation on loss of Control (480vac) or Main Power (4160vac).

All of this had to be done while keeping the pot in full running service with backup capability. Multiple forms of redundancy was built into the system, since this is a critical load.

Understanding the power supply, I did extensive testing and created a procedure for reducing power to the load by adding and removing variable capacitors, to heat up or cool down the zinc pot.

I created all integration CAD drawings to all of this.

Variable Frequency Drive Lineup Installs

Description:

Replace obsolete VFDs with new ones while trying to keep everything running. Figured out a way to do this with minimal downtime.

Lead Engineer over demo and install of all electrical and communications.

Integrated drive systems into main controllers.

Stages of Project:

• Install Lineup #1

• Commission Lineup with control power and communications

• During Limited downtime, move all cable over to new lineup

• Live commissioning and tuning of drives

• Demo old Lineup #1

• Install Lineup #2 where old #1 was

• Commission Lineup with control power and communications

• During Limited downtime, move all cable over to new lineup

• Live commissioning and tuning of drives

Zinc Pot Automatic Transfer Switch and Alarm Automation

Description:

Designed and installed dual Automatic Transfer Switch for redundant control power and SCR cooling.

Designed alarm system on 16KVA UPS downstream of redundant power supplies.

The system would announce 9 different alarming conditions over a radio APB on multiple frequencies.

If the system, lost both redundant power supplies, it would alarm that loss of power.

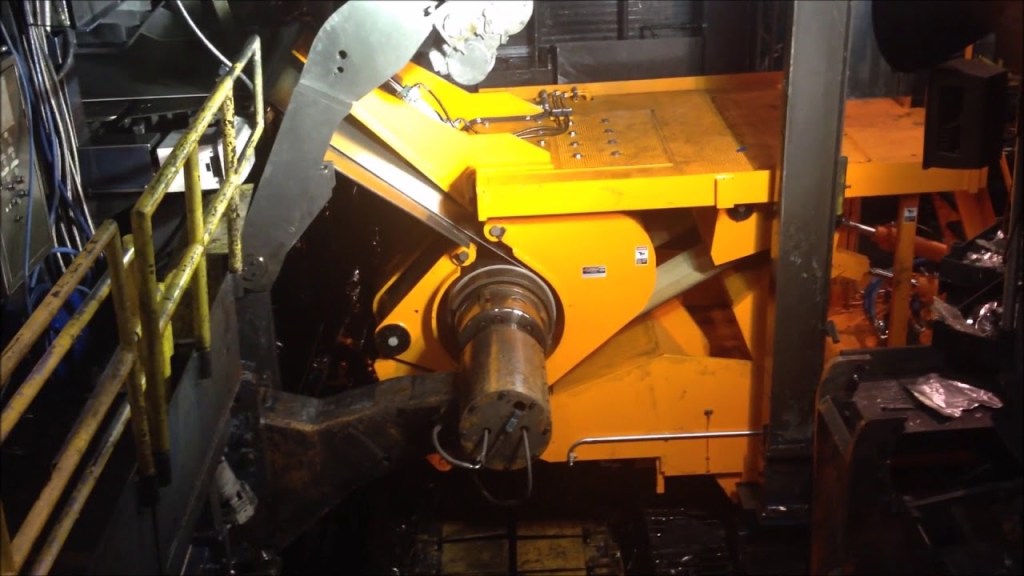

Automation of Hydraulic Belt Wrapper on Tension Leveler Line

Description:

Project Engineer for installation of belt wrapper.

Full Automation of Belt Wrapper including auto/manual operation. Including integration into line permissives and other remote equipment that uses the same space.

Created SCADA (HMI) for wrapper.

Rebuild/Automate and Subsequent Replacement of Oiler System

Description:

Part 1:

Due to obsolescence of parts and delay on Capital, company needed quick re-engineer and automation of a system.

We removed old servo pumps, drives, and piping, installed positive displacement variable frequency pumps and drives, re-piped system and added positive displacement flowmeters.

Major Automation revision to remove old logic and put the new system on a PID closed loop. Customer Extremely Pleased.

Part 2:

After CAPEX availability and production downtime was available, we managed the project of demoing and installing an Electrostatic Oiler:

Operation is fully automated::

• Set up PLC and SCADA on network

• Set up communications between 2 different PLCs

• While doing this began collecting communications and all IO data into historical collection for better troubleshooting.

• Completely rewrote all the logic in mail line PLC for oiler automation.

• Built new operations and informational SCADA screens for easy operations.

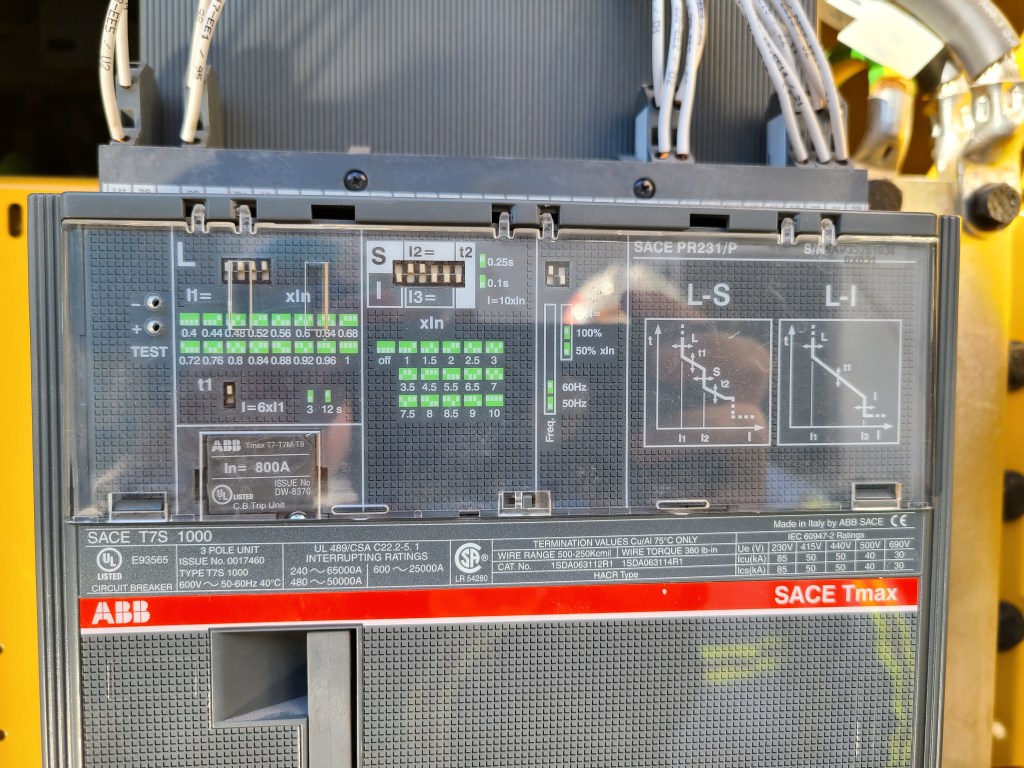

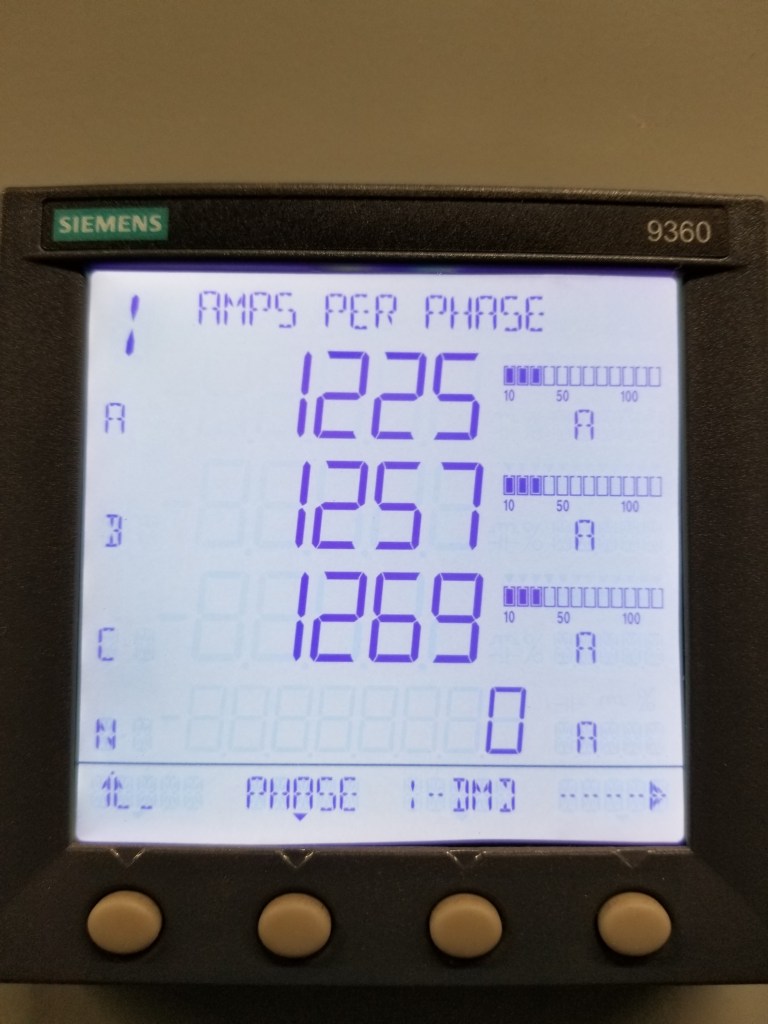

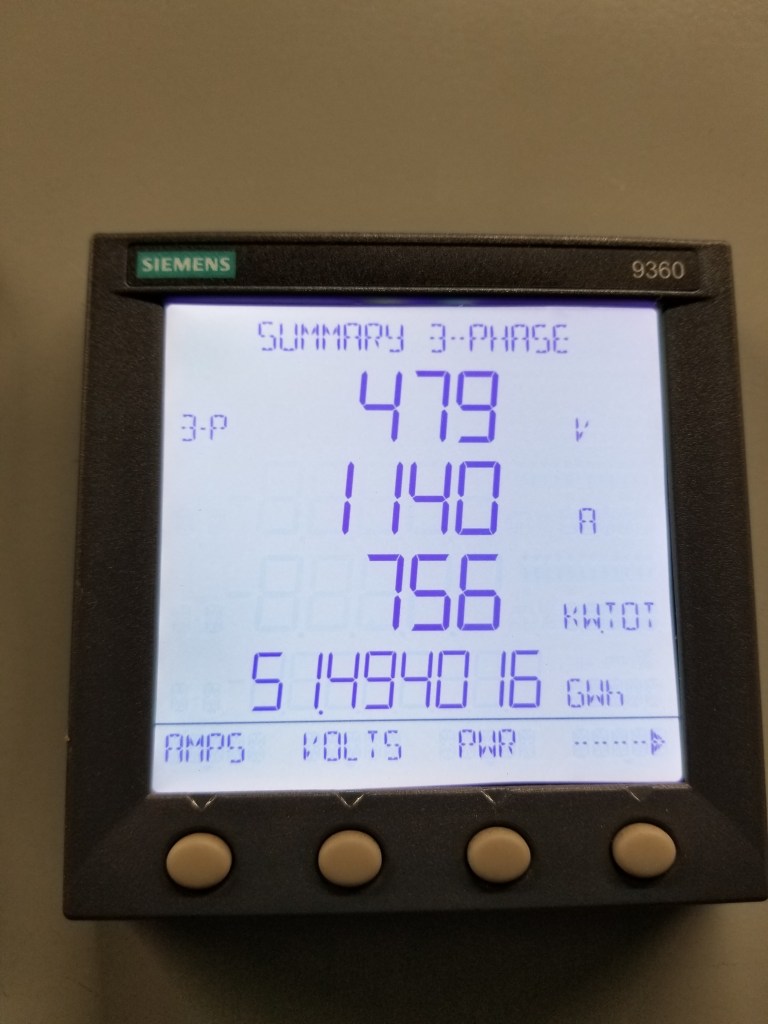

Power Systems Instrumentation Upgrades and Automation throughout Steel Mill

Description:

Implemented full system updates for full communication between relays and central control system. Consisting of:

• Ethernet and Modbus communication to Relays

• Any relays that couldn’t communicate were upgraded

• Utilized SKM to re-coordinate bus, breaker, and relay settings of distribution system.

• Automated several safety functions and added to SCADA.

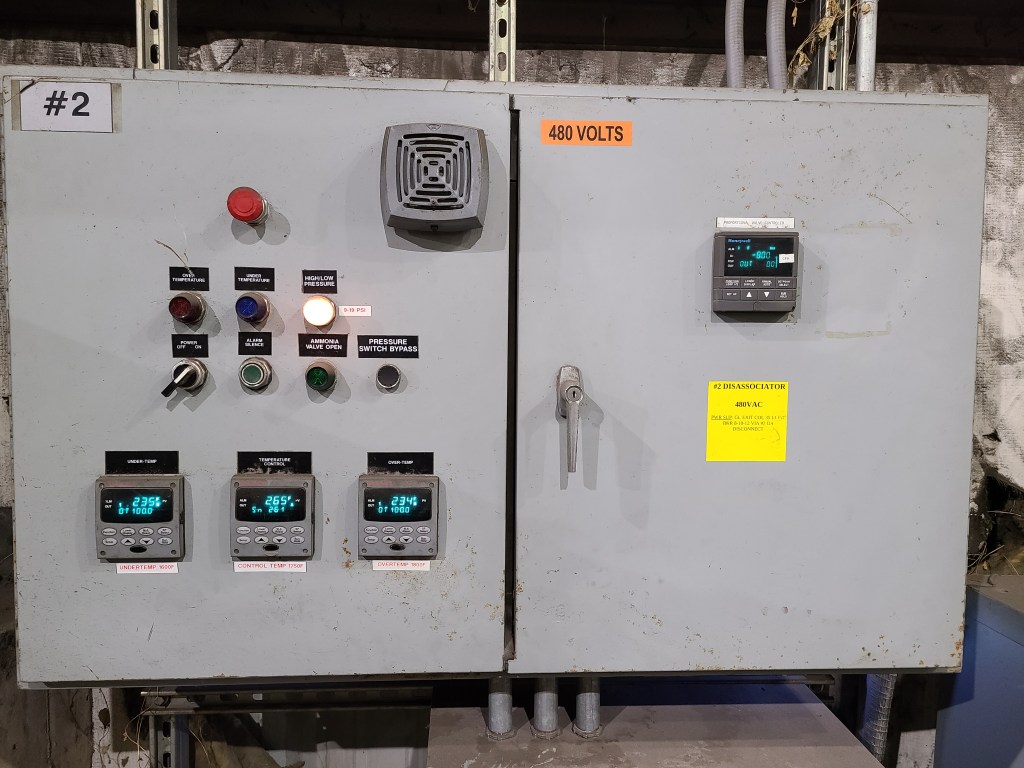

Ammonia Dissociator Installation, Automation, and Maintenance Program

Description:

Install 2 4000 SCFH Ammonia Dissociators that would take NH3 (anhydrous) pass it through a catalyst and break it down into 1 part N2 and 3 parts H2 to feed a large furnace atmosphere.

Programmed operation of dissociators, Rewired Relays and created schematics.

Installed and set up NH3 safety monitors.

Created PM schedule and Instruction Manual that resulted in a much-elevated level of knowledge of maintenance personnel.

This project allowed company to run for a 3 MONTH HYDROGEN CURTAILMENT with no incident or problem. FULL PRODUCTION the entire time.

More Projects

Installation and Comms – Stenciler

Installed new stenciler with ethernet communication with PLC.

Study and Installation – Atmospheric Monitoring Safety System

Installed 5 Analyzers that analyzed O2, H2, Dew Point and provide feedback to a PLC and programmed PLC to use the analyzers for both safety shutdown, and for automatic environmental adjustments to make cleaner product coming out of the furnace. Project was in partnership with PyroAir.

Automation – Pay Off Reel Coil Centering System

Installed lasers looking at coil to calculate position. Took known position and expected coil width from Level 2, to calculate a “best position” for mandrel expansion.

Engineering and Automation – Iron and Acid Automatic Control System

Installed Analysis system and integrated into PLC.

Coded Multi-stage PID loop to control automatic addition of acid and water based on acid and iron content, which reacted differently based on product material, thickness, width and speed.

Added SCADA screens and alarms.

Automation – Uncoiler/Double Stub Pay-off Reel Position

Used positioning lasers and solid measurements to build a model that would allow over travel of either side of a doublestub mandrel, yet they could not hit each other.

Coded an algorithim that predicted the center of a coil using a positioning laser from above, allowing operators to perfectly stub the coil on the uncoiler preventing an existing problem of mandrels striking each other and coils causing broken mandrels and falling coils.

Automation – Water Filtration System

Already installed dual train, bag-filter that had logic that wasn’t working properly, and was a constant problem.

Completely rewrote logic from scratch and now the trains are fully automated to switch trains upon a high pressure (dirty filter) and give SCADA indication of such.

Automation – Steering Unit Alarms

Automation between 3 PLCs that would communicate with SCADA system and provide alarm when the system sensed that steering rolls had a failure of valve or controls.

Also would alarm on large jumps in position, providing advanced indication before ripping product.

Install and Automation – Zinc Brush Machine Installation and Automation

Moved brush machine to a different location on line. Swapped automation to a different PLC, and integrated controls with SCACA.

Install and Automation – Width Gauge, Edge Guidance, and Side Trimmers

Installed remote IO, lasers, and camera-based edge detection and integrated into PLC and SCADA to determine edge location and width.

Used this for quality control, to control edge cutting, scrap cutting, and to hydraulically move a recoiler for straight edge guiding.

Automation – Horizontal Annealing Furnace Efficiency

Enhanced the efficiency of a continuous annealing furnace after performing an engineering study of the system

Raised combustion air temperature providing a hotter furnace when running at 100%. When not at 100%, the furnace ran more efficient.

This resulted in a 2.5% increase in production and less fuel cost.

Automation – Nitrogen & Hydrogen Maxon Safety Valves

Programmed permissives based on safety features and provided controls on SCADA without bypassing any safety features.

Automation – Automatic Brush Roll Pressure Control

Used torque of VFD driven motors to calculate load on brushes in a cleaner section and programmed meshes to move rolls closer or further away to regulate amount of cleaning done by rolls.

Automation – Fume Scrubbing and Removal System

Built and installed remote IO and Motor Controls.

Automated sprays, suction control, level control and dirty discharge.

Integrated into PLC and SCADA for controls and integrations.

Engineering and Automation – Drive Upgrade and High Temperature Capability

Removed hard-wired multi-speed drives and installed Profibus controlled Variable Frequency Drives.

Programmed Var Frequency control in PLC.

As part of upgrades, also programmed new safety controls to sense high-temp equipment and adjust setpoints based on equipment installed.